Line fall protection belongs to the group of permanent systems protecting against fall from a height, which is characterized by firm fastening to load bearing structure of a building and is its integral part. It is assumed that its usage will be long-term, often comparable to exploitation of the building itself. Fall protection systems provide constant security during work on a height across the whole length of the system. That is why they are designed wherever providing user’s freedom of movement is necessary. Huge functionality of the system consist of the fact than multiple people can use it at the same time. In the following part of the article we will describe precise characteristics of different systems along with the places and situations where they should be used.

Lifeline fall protection Absorber

Primary classification of fall protection systems involves two main categories. They are linked by common construction elements and assumptions but basic differences in build and characteristic we will describe below:

Horizontal lifeline systems

Main task of horizontal line fall protection systems is to provide protection against fall from a height during movement along flat or slightly inclined surface. Universality of such systems and possibility to install it to many different load bearing elements allows to using it in hard-to-reach places, for example on railway bridge to help with exploitation of rolling stock, to service cisterns of truck semitrailers, to protect telphers, to build bridge span or to protect people during roof installations (photovoltaics, skylights etc.) To secure specialized works we use overhead systems with self-braking devices, situated above the user during job. Means of montage are dependent on the type of load-bearing structure and material from which it is made of. In today’s world we don’t have any problem with fastening fall protection system to any surface that meets the load-bearing requirements. Even isolation layers covering construction are not an obstacle. Fall protection line is often exposed to unfavorable weather and environmental conditions. To provide long-term durability and hassle-free exploitation it is made of high quality acid-resistant steel.

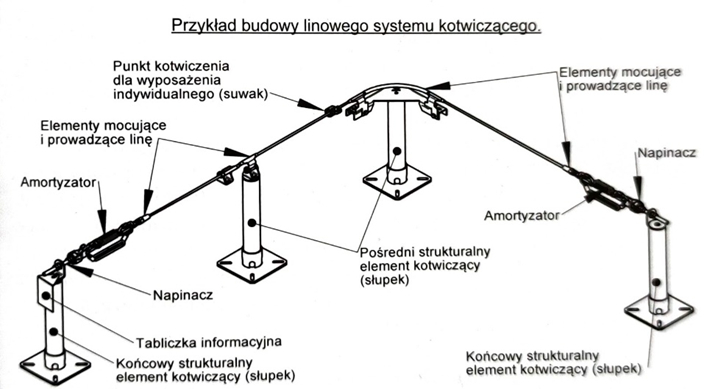

Example of line fall protection system’s construction

Anchorage point for personal equipment (trolley)

Elements mounting and guiding the rope

Shock-absorber

Tensor

Information plate

Final structural anchorage element (pole)

Middle structural anchorage element (pole)

Construction for rope is created by initial, final and middle points used with wider spreads of the system. In case of such middle points usage we talk about multi-span system. Extreme points are equipped with shock-absorber and tensor respectively, which are responsible for the line stretch. Additionally deign of such system can foresee any change in direction keeping continuity thanks to using special cornering poles. Depending on the type of project and technical requirements we can also use outside shock-absorber or one integral with extreme anchorage point.

Vertical lifline systems

Vertical lifline systems

Main task of vertical fall protection is stopping a fall. They are used wherever there is vertical movement and users are in danger of falling form a height. Most often this kind of protection is designed to secure vertical ladders. Their primary element is guideway made of steel rope or rail. In our article we will focus on the former type.

Just like in horizontal systems extreme anchorage points equipped with shock-absorber and tensor respectively are responsible for rope’s support and stretch, if system’s length demands their usage. Very important element of vertical protection is a trolley or a slider. It is installed on the guideway made of steel rope and to this element worker is directly connected. Trolley can move upwards along the guideway and also downwards at slow pace. This way It can follow the user both during ascent and slow descent. Trolley or slider is task with directly preventing possible fall. During falling (rapid downwards movement) the device locks itself on the guideway protecting the user against the fall. At the same time it limits braking force to not exceed 6kN. This work characteristic makes so vertical line fall protection systems are not included in anchorage device group (contrary to the horizontal systems) but to the connecting and shock-absorbing devices which have to function on dampening the fall. Vertical systems are subject to EN353-1 norm.